Material Resource Planning

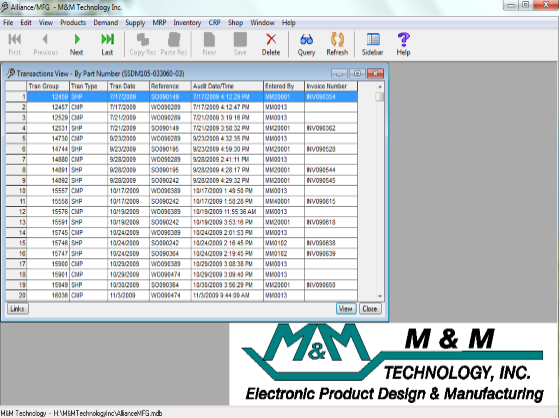

M&M Technology employs a demand driven Materials Resources Planning (MRP) system. Customer orders and/or forecasts establish demand which ensures that appropriate materials are available for production and the necessary products are available for customers to avoid shortages. MRP also keeps costs down by maintaining the lowest possible inventory levels. Lastly, the MRP system allows optimal planning of manufacturing functions, delivery schedules and purchasing.

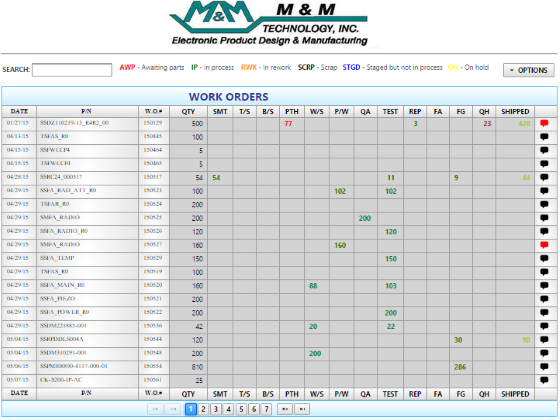

In addition to the MRP system, M&M Technology uses a customized state of the art software that tracks all work order production flows in a daily manner. This software keeps managers up to date with real time floor production information which in turn allows them to make better decisions to better satisfy customers.

Inventory Management

|

Purchasing

|

Production

|

Special Services

|

MRP System |

Real Time Floor System |

At M&M we standardized our system to better satisfy customers

Our software helps production and management make better decisions

M&M Technology MRP system keeps cost down

optimal planning of manufacturing functions, delivery schedules and purchasing

For More information

About our custom electro-mechanical assembly capabilities, or our other products and services, please contact us at +1 704 882 9432 or click the links below